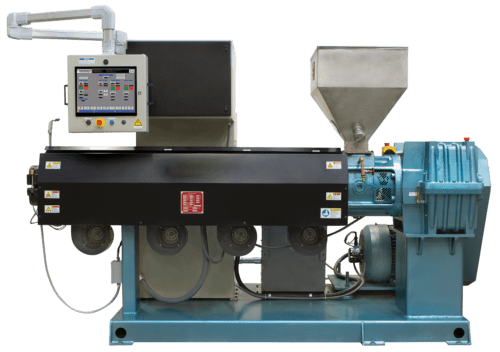

Extrusion Processing

Our extrusion department has a number of extrusion lines giving us flexibility to make parts as small as 1/4″ and up to 9″+ while varying shape and material.

Extrusion

With 15+ main extrusion lines throughout the company we can process a mix of materials to multiple shapes meeting your production requirements.

Co-Extrusion

Utilizing smaller extrusion machines we have the capability to co, tri or quad extrude materials allowing a mix of rigids, flexibles and cap to create the ideal part for application.

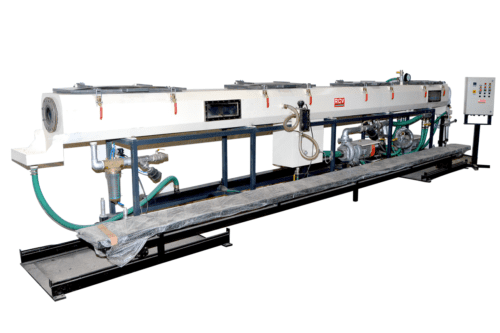

Cooling

The extrusion process requires heat but cooling is arguably more important to shape and create parts. We use various cooling methods to meet tolerance requirements and create consistency in extruded components.

Air

Water

Vacuum

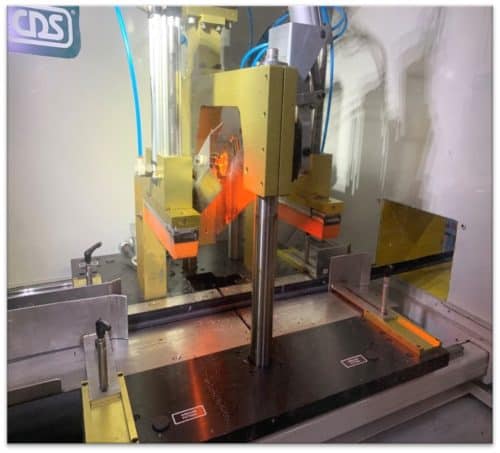

Cutting

We have the capability to cut long lengths, short lengths, tight tolerance or rough tolerance.

Saw

Blades

Knife

Value Added Services

Does your extrusion need more once it comes off the line? Our value added services can finish a lineal extrusion and have it turn key for your operation.

- Drilling

- Punching

- Close Tolerance Cutting

- Embossing

- Printing

- Secondary Material – Tape / Adhesive

Additional Services

Engineering Support

Dedicated engineering team to assist with your application needs. Providing material guidance, part manufacturability suggestions or continuous improvement on our manufacturing floor.

Labeling

Custom labeling for warehousing, tracking and quality control.

Packaging

Climatech can create custom packaging, use returnable packaging or work with your needs to make sure product arrives efficiently.

Logistical Support

Need to limit your inventory? Our team can manage inventories, ship to forecasts and deliver just in time.